The making of the exclusive Australian Stockman’s Saddlery World Cup Saddle

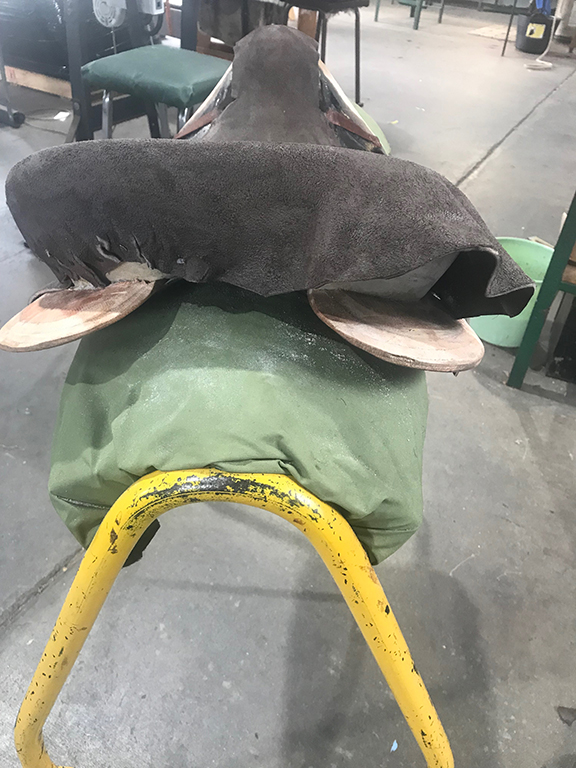

7. Sewing seat in

Hand sewing the seat to the flaps

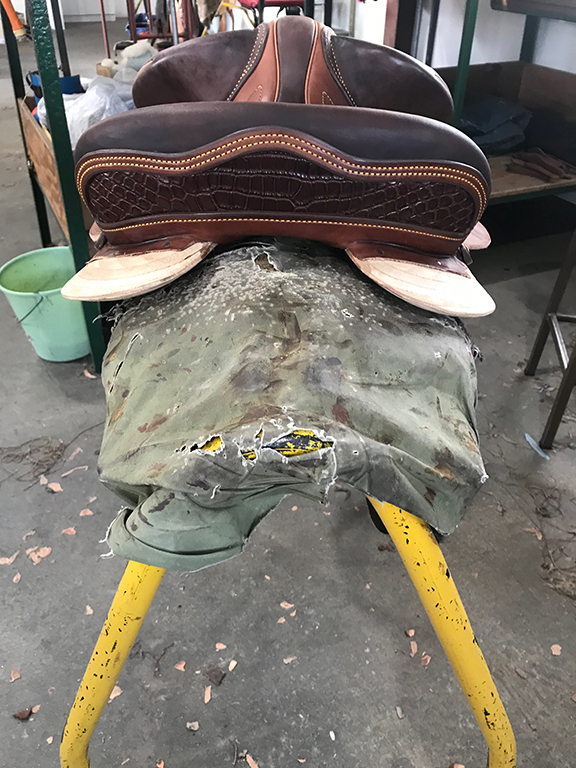

9. Skirts

The skirts are wet and moulded to the tree, then rigging plates are added along with the crocodile inlays. They are then laced together and put on the saddle.

10. The finished product

Ready for work or play.